Technology DevelopmentHydrodynamic Engineering

This Group focuses on the high-fidelity evaluation of flows around ships and offshore structures, to enhance fuel efficiency and safety of ships and offshore structures. State-of-the-art hull forms have been developed through these activities.

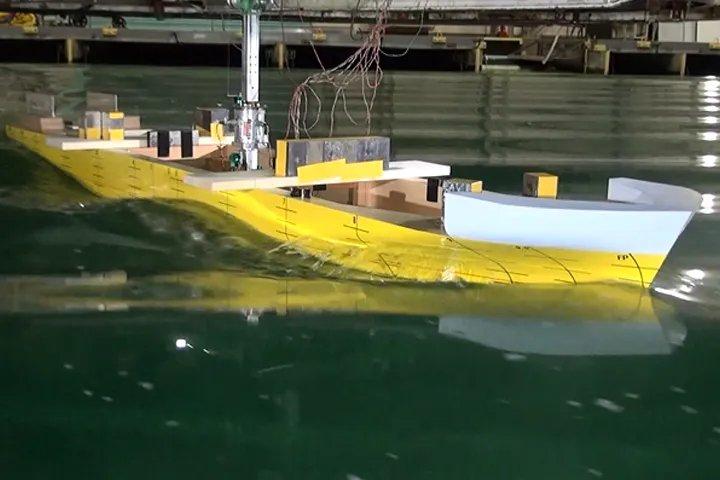

Low sea-margin bow shape

Our development; Ax-Bow®, LEADGE-Bow®, and SP-Bow® reduce resistance in waves. Ax-Bow® is the world’s first technology that successfully reduced resistance by its sharp waterline shape and it was first applied to actual vessels in 2001.

High performance based on basic hydrodynamics technology, such as Low sea margin, fuel efficiency and high maneuverability, are our major strength.

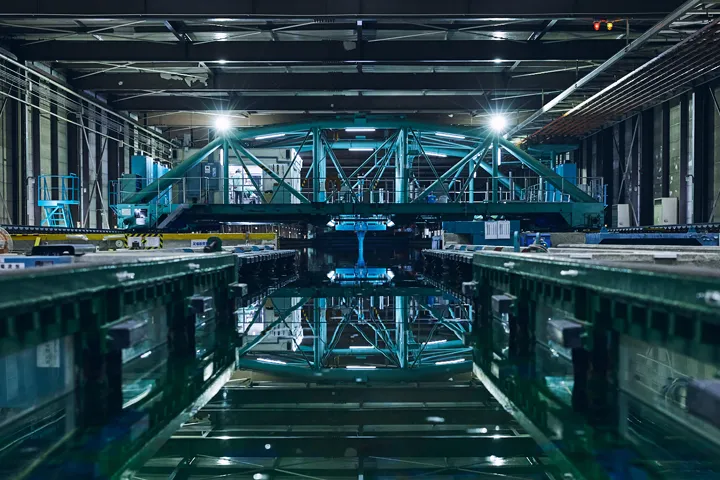

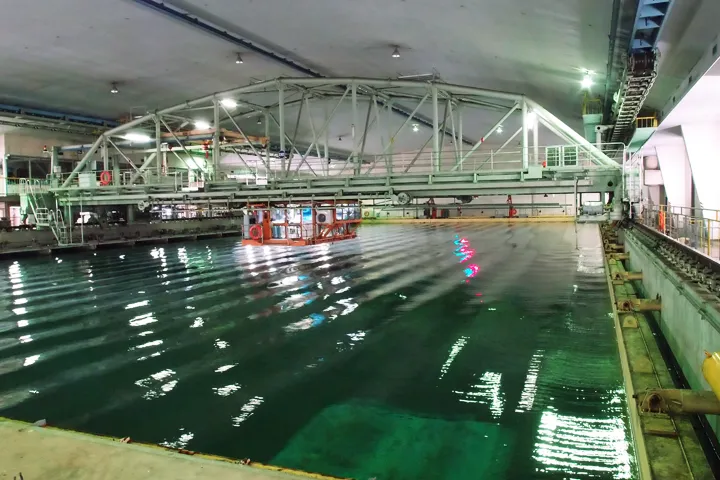

Tank test

JMU has one of the best facilities in Japan, that reproduce various sea conditions and perform large-scale tests closer to the actual scale.

(L: 240m x B: 18m x D: 8m)

(L: 70m x B: 30m x D: 3m)

The importance of energy-saving ships is increasing in order to reduce greenhouse gas emissions from ships.

Our strengths in high fuel efficiency and various developments that reduce wave and wind resistance are attracting growing interest from an environmental perspective.

Energy saving duct and SURF-BULB®

Super Stream Duct® (SSD®) and Semi-Circular Duct reduce the fuel consumption by about 3~8%. They recover the energy loss due to longitudinal vortices generated at the stern of full ships such as VLCC or Bulk Carrier and generate thrusting forces. More energy saving is possible by using these ducts together with SURF-BULB® which is installed behind a propeller.

SURF-BULB® (Swept-back Up-thrusting Rudder Fin with BULB) reduces the fuel consumption by about 3~5% by converting the rotational energy behind a propeller to the thrusting force.

For full ships such as VLCC or Bulk Carrier, more energy saving is possible by using SURF-BULB® together with the energy saving duct (SSD®) which is installed in front of a propeller.

Super Stream Duct® (SSD®) and Semi-Circular Duct reduce the fuel consumption by about 3-8%. They recover the energy loss due to longitudinal vortices generated at the stern of full ships such as VLCC or Bulk Carrier and generate thrusting forces. More energy saving is possible by using these ducts together with SURF-BULB® which is installed behind a propeller.

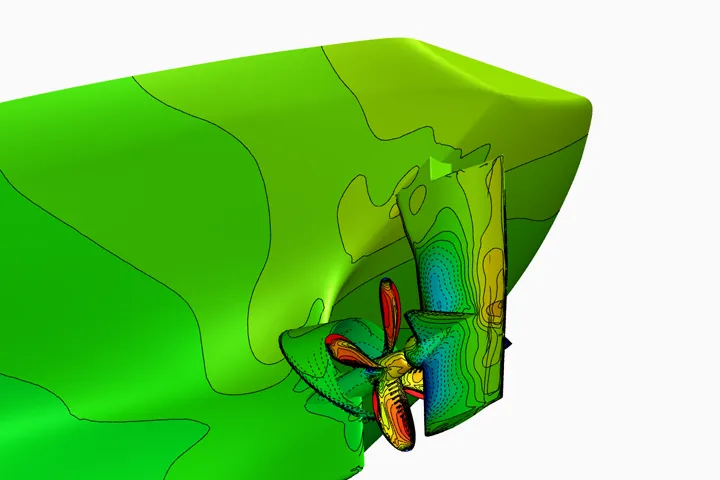

Contra-rotating propeller and rudder Bulb

Contra-Rotating Propeller (CRP) consists of two propellers which are aligned in front and behind and rotates in opposite direction each other. The propulsive efficiency is improved by the behind propeller by recovering the energy loss due to rotational flow behind the fore propeller. Now, CRP is adopted for VLCC, Bulk Carrier and domestic ships with electrical propulsion system and contributes to the improvement of fuel consumption and reduction of CO2, Nox and Sox emission.

Behind a Contra-Rotating propeller, because there is no rotational flow to be converted to the thrusting force by fins, the rudder bulb with finless SURF-BULB® is adopted for CRP.

L.V. Fin

L.V.Fin (Low Viscous resistance Fin) is a pair of triangle stern fins installed in front of a propeller on both of starboard and port side. L.V.Fin straightens the complex stern flow including bilge vortices and reduces the hull resistance. About 2~3% energy saving is confirmed in speed trial of full ships. Because of simple form and easy installation, L.V.Fin has been adopted to many ships.

Low Wind resistance Accommodation

Square corner cut accommodation reduces wind resistance of ship by about 10~15%. This technology is put to practical use for reducing sea-margin together with Ax-Bow® or LEADGE Bow®.