Performance in Actual Sea

The performance of ships still evolves.

What technology we are focusing on

We are developing various technologies to improve ship performance in rough condition.

We will take a variety of approaches, including hydrodynamic engineering to reduce the resistance of water and air received on ships, structural engineering to ensure safety in a fierce ocean conditions, and information technology to collect the data necessary for them.

Why is that technology necessary?

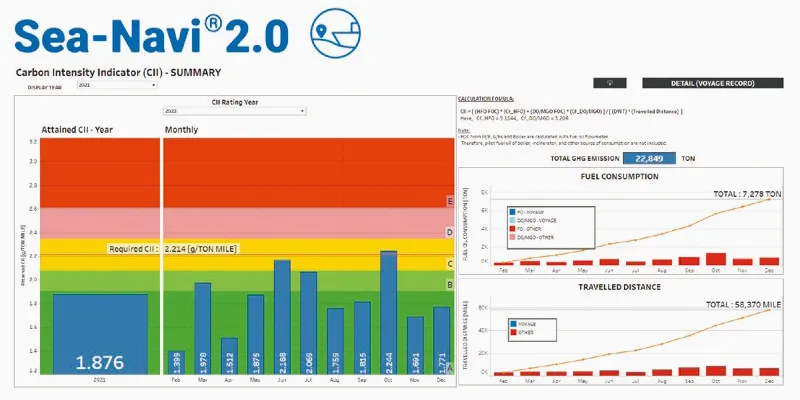

Fuel efficiency during voyage is an extremely significant factor for ships. As global warming has become more serious, the importance of energy-saving ships is rising in order to reduce greenhouse gas emissions from ships. JMU is focusing on improving the performance of ships in actual seas.

It was not until the 2000s that a system was developed to monitor ship in detail during voyage. Until that time, ship building was based on hypothetical water tank tests and simulations, and the reality is that it does not always match the data of actual ships in service.

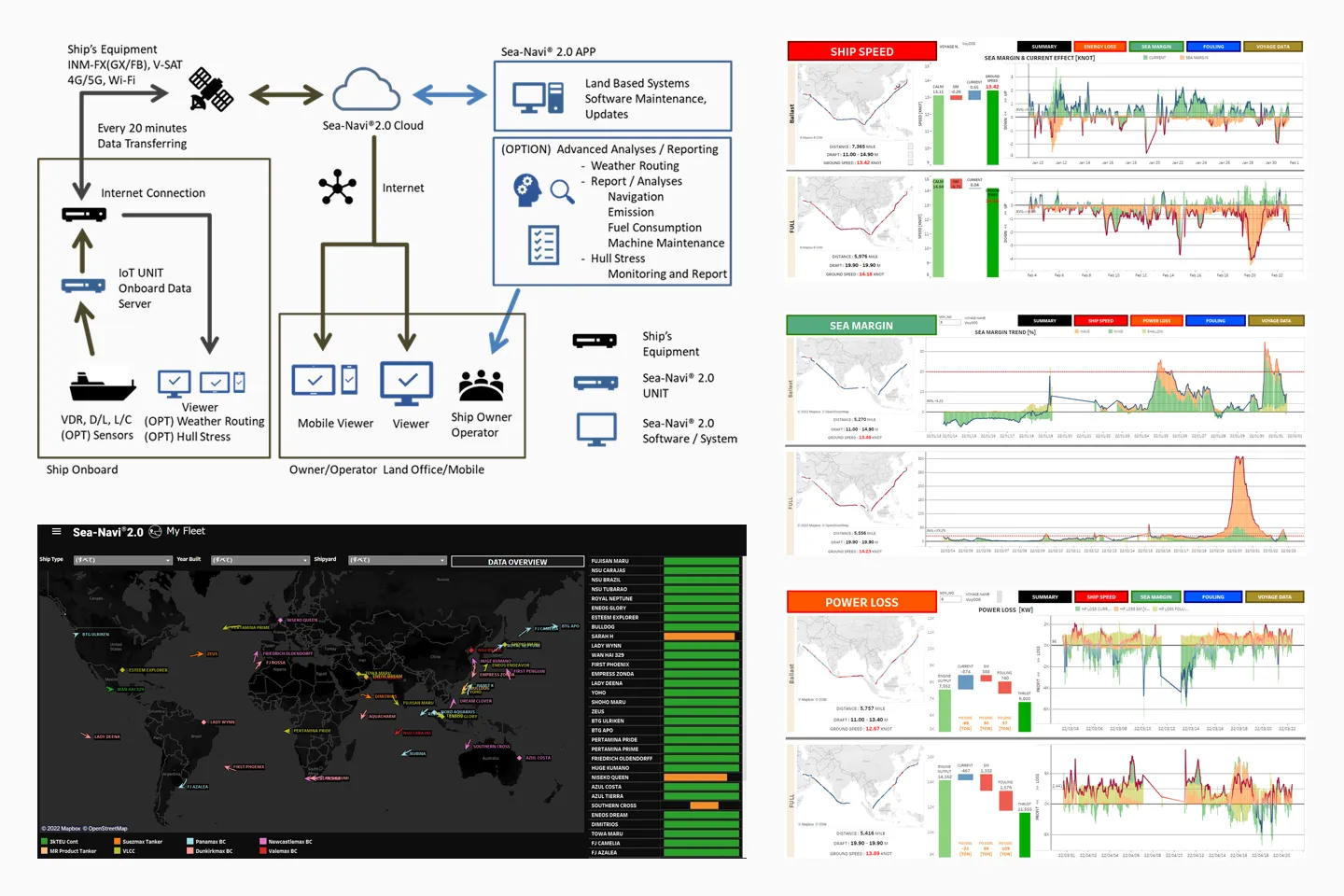

JMU has strengths in calculation processing and data visualization with a “ship-specified” monitoring system combined shipyard’s unique know-how, which includes model test data, post-service monitoring data, and ship knowledge. It has potential for development of ship building, which has many physical and regulatory restrictions.

In addition, JMU has R&D personnel specializing in hydrodynamic engineering and structural engineering which are necessary to find the shape of a ship with less water and air resistance. In addition, the facilities enable diverse research, including the world’s largest tank and seakeeping maneuvering tank that can create various waves. Making full use of the research of our specialized team and well-equipped facilities, we develop high-performance ships with minimal resistance.

How to realize that technology

It is necessary to have technology that maintains a balance between various performance such as the shape, structure, and safety of the ship to improve the performance of a ship in actual sea. In addition to the development of ship shapes that perform even in waves and wind, the research, design, and manufacturing sections in our company are collaborating on various issues such as the development of technology to measure what kind of phenomena are actually occurring in the sea, the structural monitoring by collecting and analyzing the hull structure response and acceleration.

The shape of the bow, which first receives water resistance when the ship moves forward, greatly affects the propulsion power and fuel efficiency of the ship.

JMU has designed a number of bow shapes such as the Ax-Bow (Ship of the Year 2001 award, Japan) and LEADGE-Bow® through research on hydrodynamic and structural engineering. The sharp tip reduces the resistance received from the waves, and the bow lowers the drop of ship speed in waves has succeeded. The performance is highly evaluated.

For data analysis, we designed the ship based on numerous simulations and tests and monitored by Sea-Navi® to collect the ship’s navigation data after delivery. Measure the actual flow of water at sea, verify and compare hypotheses. Based on the results, we repeatedly brush up the design and check the performance.

Monitoring technology is very important not only for ship development but also for supporting operation.

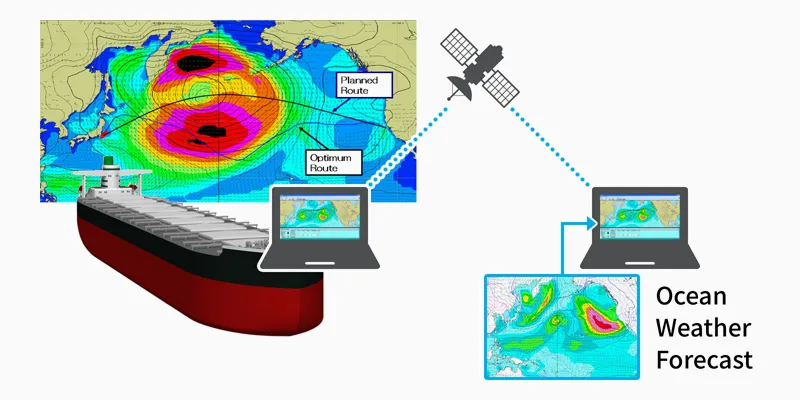

By presenting the optimal route in consideration of fuel efficiency and avoiding bad weather to the destination, corrected route depends on sea conditions, and the prompt presentation of the evaluation of operational performance, Sea-Navi® leads to fuel-efficient and safe operation.

Vision

Environmental issues and advanced digital technology accelerate significant technological transformations in the long history of ships.

By correctly estimating the performance of any ship with any fuel and specifications, improving technology, and pursuing the ideal ship that best meets the needs of the time, a new type of ship may be appeared beyond our imagination.

In order to improve these new ships, it is essential to improve monitoring technology that can collect detailed information in real time. In addition, digital twin technology is used to reproduce a ship operating in real sea area in cyberspace by combining monitoring and simulation technology. Through these initiatives, we will pursue performance in actual seas including after the delivery of the ship, and release products that will make customers feel more beneficial.